- Up to 38 independently controlled axes allow for the forming of complex shapes

- Up to 5 different motions inside the yoke greatly decrease material waste

- Up to 3 hydraulically adjustable die tables allow long dies to be utilized

- Yoke swing up to 60 degrees

- Tangency tracking device decreases setup time for new part programs

- CNC control for high accuracy and repeatability

- Optional bulldozer for reverse contour forming

- Easy integration of automated die handling system

- Proven design, providing quick and safe operation

- CAM (Computer Aided Manufacturing) Tool design/manufacture and on-site set-up

Typical parts produced on this machine range: Fuselage parts up to 50 feet long, fuselage parts requiring counter-forming capability

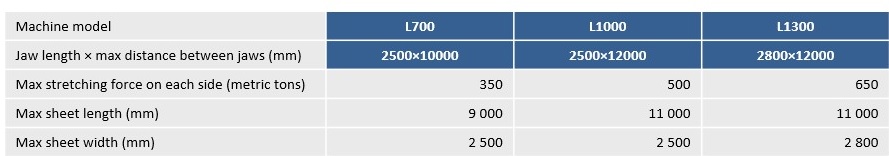

Standard machines:

The table here under is an indication to give you an overview of the machines we already installed. Each machine can be customized according to your requirements.

FEL Standard features and peripheral equipment

FEL Optional features and peripheral equipment