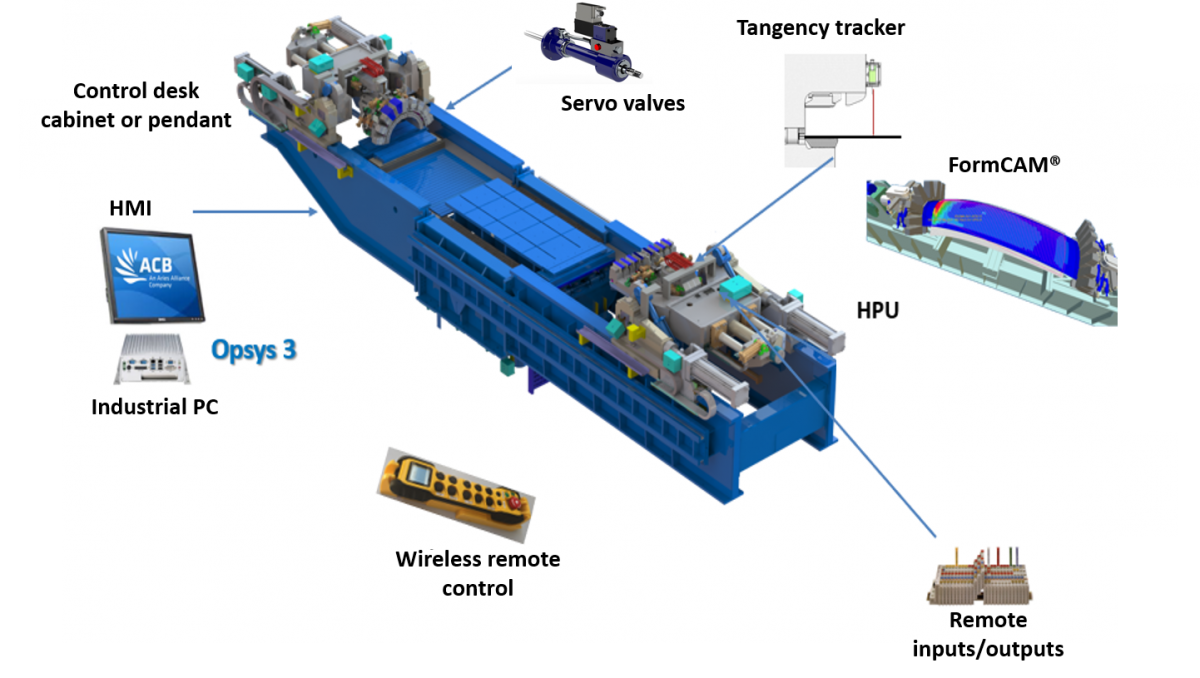

Unique features:

- Flexibility to make longitudinal and transversal parts

- Up to 38 independently controlled axes allow for the forming of complex shapes

- Up to 5 different motions inside the yoke greatly decrease material waste

- Up to 3 die tables allow long dies to be utilized

- Yoke swing up to 90 degrees

- Tangency tracking device decreases setup time for new part programs

- CNC control for high accuracy and repeatability

- Optional bulldozer for reverse contour forming

- Easy integration of automated die handling system

- Proven design, providing quick and safe operation

- CAM (Computer Aided Manufacturing) Tool design/manufacture and on-site set-up

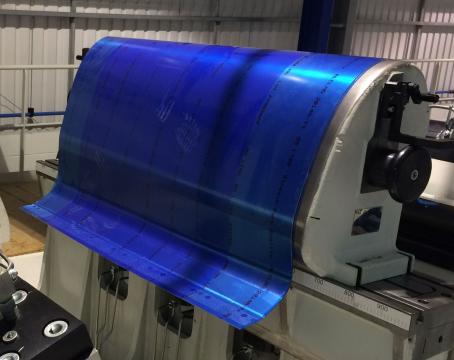

Typical parts produced on this type of press are: Complex contours around cockpit, long fuselage parts up to 50feet, fuselage parts requiring reverse contour forming capability, leading edge parts

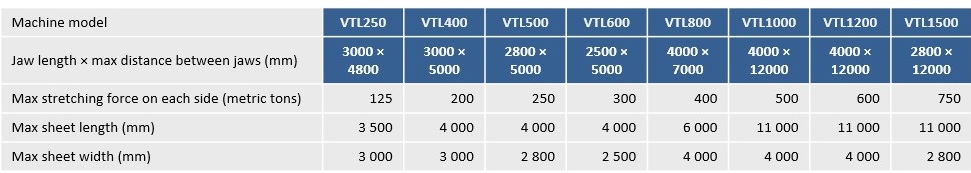

Standard longitudinal sheet stretch forming machines.

The table here under is an indication to give you an overview of the machines we already installed. Each machine can be customized according to your requirements.

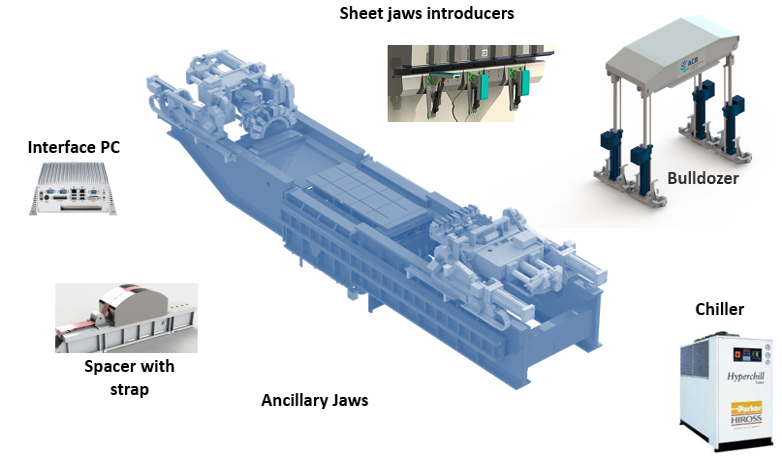

Standard machine features and peripheral equipment

Optional machine features and peripheral equipment